Pallet wrap, or stretch film, is too often overlooked as part of any business’s logistics process, and the procurement cycle. It is usually the case that “we do what we always do, because that seems to be OK”, where in reality, companies such as Surepack have proven that reviewing and auditing the pallet wrap process can deliver a significant plastic reduction, and lower overall costs per pallet wrapped.

As an expert in logistics packaging, Chuen Lau (founder of Surepack), has over 30 years experience within the stretch film industry, and has helped brands across the UK to improve their pallet wrapping process.

Chuen has identified that operations and warehouse teams don’t always know the real cost and efficiency of how they’re wrapping pallets, or how to conduct a pallet wrap evaluation. The Surepack team works with supply chain operators to analyse existing processes and materials, helping identify and drive efficiencies, effectiveness and improve sustainability.

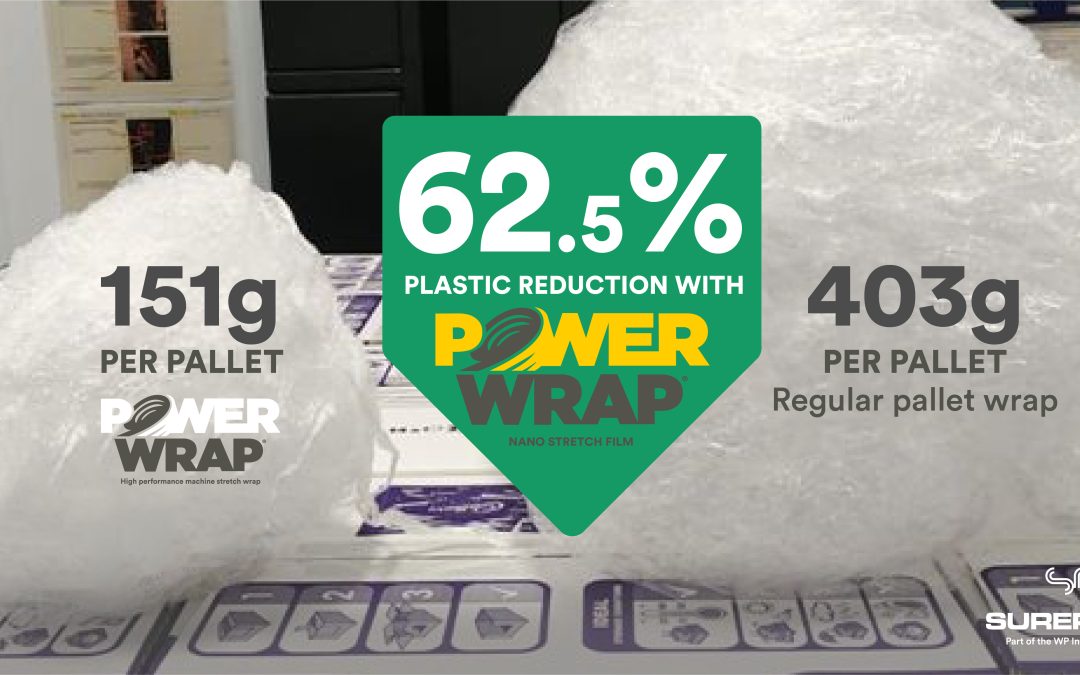

Part of this analysis that Surepack undertakes is to wrap the same pallet in a business’s regular stretch film, and then with PowerWrap – a nano technology pallet film.

More often than not, using exactly the same machine settings and pallet load, PowerWrap uses substantially less plastic per pallet. The example above shows a huge 62.5% reduction in the weight of plastic used to wrap a pallet of boxes of confectionery, at a leading UK brand manufacturing plant. This reduction from 403g of stretch film, to 151g when PowerWrap was used, also gave a better hold force (for increased load stability) and much greater clarity of the wrap, enabling barcodes and products to easily be scanned whilst wrapped.

Chuen from Surepack explains that PowerWrap® pallet film enables logistics teams to save time, cut plastic waste and reduce their pallet wrapping costs, by making the most of the latest technological developments in stretch film.

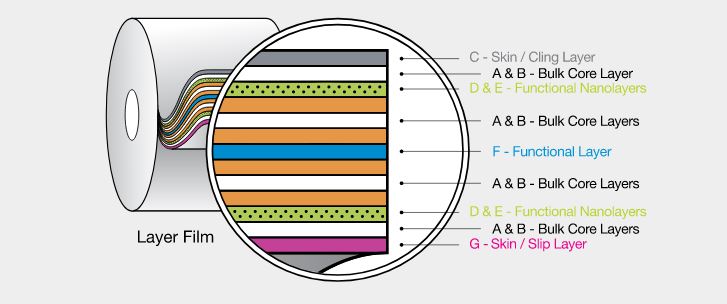

PowerWrap pallet wrap is made up of multiple layers of polymers, which are not commonly used in more conventional pallet films in the UK. Each of these polymer layers are selected, blended and then extruded to create a nano film that is designed for optimum hold force, tear resistance and is ultimately much stronger, and lighter, than older specification pallet films.

The engineered layers of polymer in PowerWrap® is the same principle as in plywood and bullet proof glass – making it virtually unbeatable.

At Surepack, Chuen and the team of logistics packaging experts, are happy to visit warehouse and distribution centre sites across the UK to help audit and review pallet wrapping processes.

To contact Chuen Lau of Surepack, call 0117 960 8706 or email sales@surepack.co.uk